6 June 2025

In our latest Holmbury blog, we dive into the risks of galvanic corrosion—what it is, why it happens, and how to prevent it when working with hydraulic systems. Read the full post below, to stay ahead of potential system failures.

When using Quick Release Couplings, it is important that the male and female components are compatible to avoid the risk of galvanic corrosion.

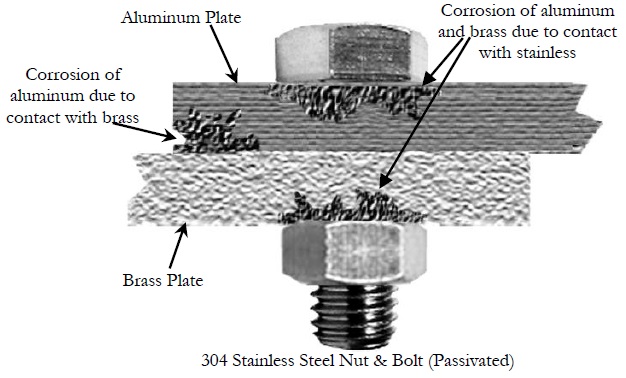

Galvanic corrosion occurs when two different metals are in contact with each other in the presence of saltwater or moisture. One metal corrodes while the other remains unaffected. To prevent this, compatible metals should be selected.

This is good practice regardless of the application. As carbon steel and stainless steel are commonly used in Quick Release Couplings, it is essential to apply the same precautionary measures.

During a recent equipment refurbishment for a client operating in a marine environment, it was found that the Quick Release Couplings could not be disengaged. Upon inspection, the female coupling was made of carbon steel, and the male was stainless steel. Galvanic corrosion had occurred, effectively bonding the two parts together. To prevent recurrence, the client opted to use stainless steel for both the male and female couplings.

Holmbury supplies Quick Release Couplings in a range of metals that are designed, tested, and approved for specific applications and environments. For guidance on selecting the most appropriate coupling, please contact our team.